Thermoplastic Elastomers

Thanks to their molecular structure, the thermoplastic elastomers have the elastic characteristics of the elastomers, but they can be processed as thermoplastic materials with remarkable advantages both in processing easiness and flexibility.

Several applications fields:

• TPO polyolefin matrix, modified with EPDM • TPV polyolefin matrix, modified with vulcanizable EPDM • TPE styrene co-polymer SBS, modified with styrene resins or polyolefin • Styrene co-polymer SEBS base, modified with styrene resins or polyolefin TPE • TPU thermoplastic polyurethane

SBS - SEBS - TPV:

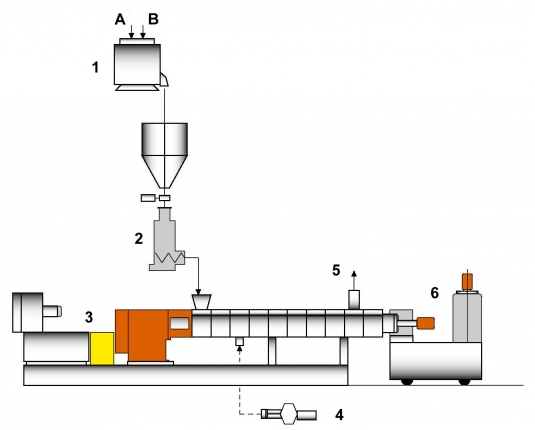

1 turbo-mixer, 2 gravimetric feeders, 3 MCM co-rotating extruder, 4 gravimetric feeders for liquid components, 5 degassing, 6 hot-face pelletizer. A = Rubber, Polymer, Filler, Additive. B = Oil

TPV with separate feeding:

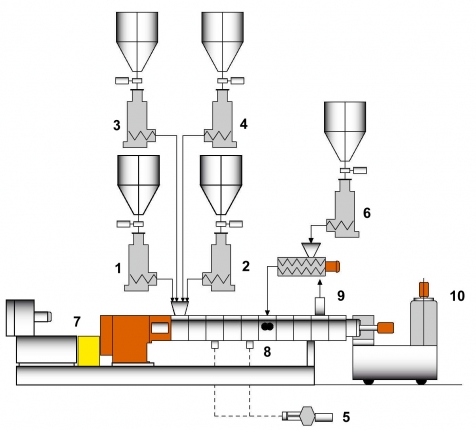

1 gravimetric feeders for rubber, 2 gravimetric feeders for polymer, 3 gravimetric feeders for fillers, 4 gravimetric feeders for additives, 5 gravimetric feeders for liquid components, 6 gravimetric feeders for additives, 7 MCM co-rotating extruder, 8 side feeding unit, 9 degassing, 10 hot-face pelletizer