Direct Extrusion Systems

What is an extrusion (direct) line?

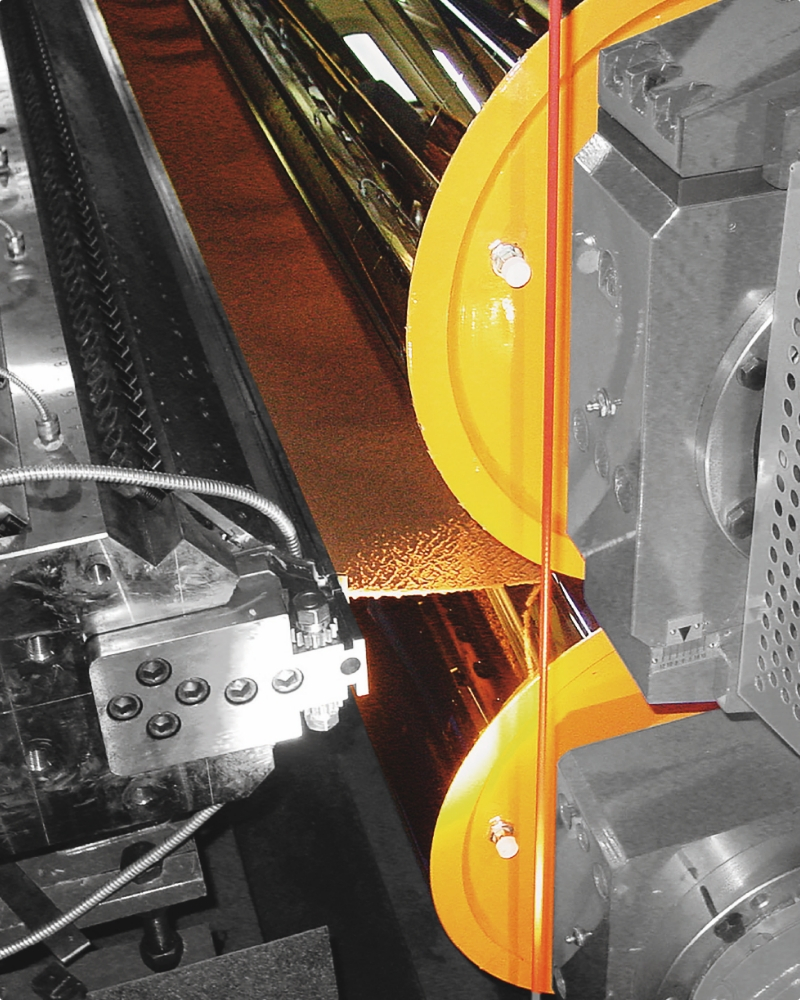

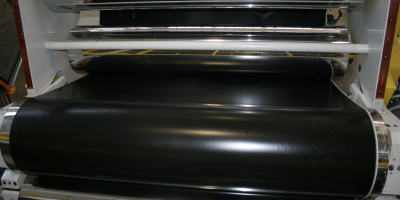

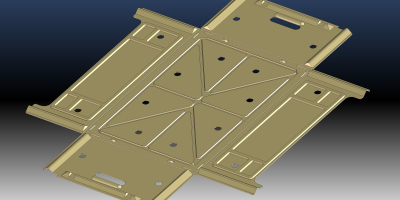

A sheet extrusion line consists of an extruder (single or twin screw), often equipped with a screen changer and a gear pump feeding a flat sheet die.

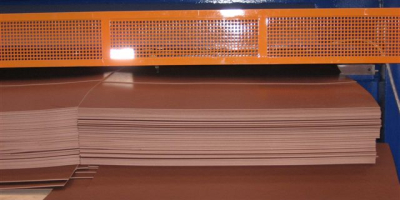

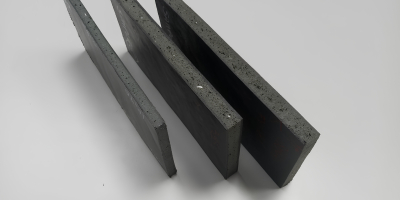

In Direct Extrusion (or In-Line Compounding) the extruder is a twin screw co-rotating unit combining in one step the compounding and the extrusion phases delivering great advantages like energy savings, fewer investment costs, and a leaner production process.

This method secures a very economical production process removing the need for re-melting and minimizing the shear stress of the material. Moreover, the thermal stress derived from a second melting is totally eliminated together with the energy costs for the cooling and re-heating of the material.

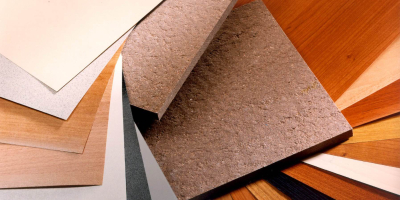

ICMA, by combining its top-end technology in co-rotating compounding and calendaring can supply Direct Extrusion turn-key lines for Custom Applications in several industries.

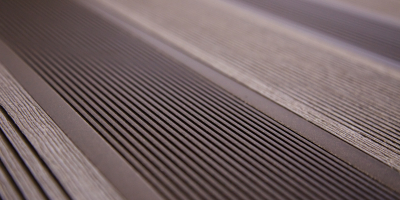

The Calenders are designed and manufactured in Icma in order to grant maximum integration and quality control of the overall extrusion line.

Icma is therefore a turn-key supplier for your extrusion line, no need to have more than one supplier or internal engineering capabilities for your new line!