Mineral / Filled Compound / Polymeric Alloys

The preparation of filled, reinforced compound and polymeric alloys represents today an indispensable requirement in various fields such as the automotive industry, the “white goods”, the building industry, and so on.

The advantages obtained using these composite materials guarantee an improvement of the mechanical properties, the impact strength, and the ability to better stand thermal stress with respect to the original raw materials with the great benefit of the functionality of the final item.

For many years ICMA plants are in the forefront to guarantee the best results in productivity and quality for the producers involved in this field.

Filled compound:

→ Mineral-filled compounds (CaCO3, TiO2) up to 80%

→ Organi- filled compounds

→ Flame retardant compounds

→ Polymeric alloys

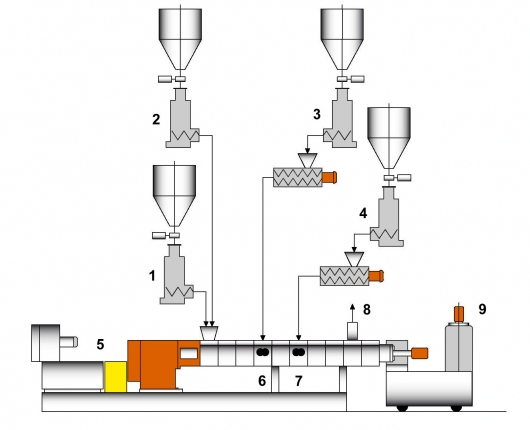

1 gravimetric feeder for polymer, 2 gravimetric feeders for additives, 3 gravimetric feeders for fillers, 4 gravimetric feeders for fillers, 5 MCM co-rotating extruder, 6 side feeding unit, 7 side feeding unit, 8 degassing, 9 hot-face pelletizer.

Glass reinforced compound:

→ Techno-polymers compounds reinforced with glass fibres

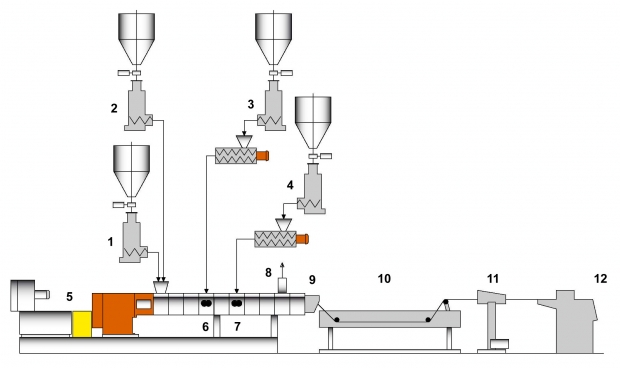

1 gravimetric feeder for polymer, 2 gravimetric feeders for additives, 3 gravimetric feeders for fillers, 4 gravimetric feeders for glass fibres, 5 MCM co-rotating extruders, 6 side feeders, 7 side feeders, 8 degassing, 9 strands-die, 10 cooling tank, 11 air blade, 12 pelletize.