Compounding & Masterbatch Systems

What is a Compounding Extruder or Masterbatch System?

A compounding or Masterbatch extruder is a continuous and multi-stage process machine that typically uses a co-rotating design technology where generally polymers and additives are intensively mixed each other to produce a material with enhanced properties.

What does the extruder do?

For STANDARD COMPOUNDING, we offer dedicated high-performance systems to reduce production costs.

We supply extruders and complete systems with all components, including turnkey solutions.

For customers devoted to SPECIALTY COMPOUNDING, we offer solutions with high technological control and extraordinary versatility.

Overall ICMA serves the Compounding and Masterbatch industry with state-of-the-art technology solutions to cover the widest range of formulations.

What is Masterbatch and its usage?

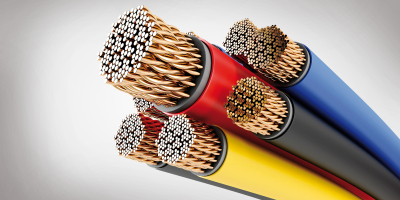

A color Masterbatch, or color concentrate, is a granule used for coloring thermoplastics. It consists of one or more colorants and a polymer-specific carrier resin. The composition of a color Masterbatch is called its recipe.

What are the different Masterbatch applications in production?

For each different plastic product, different plastic resin raw materials are used. This article will give you the most comprehensive overview of the application of different types of plastic resins in the manufacture of plastic products.

- Color masterbatch

- Filler Masterbatch

- Plastic additives

- Pigments

- Plastic & rubber chemicals